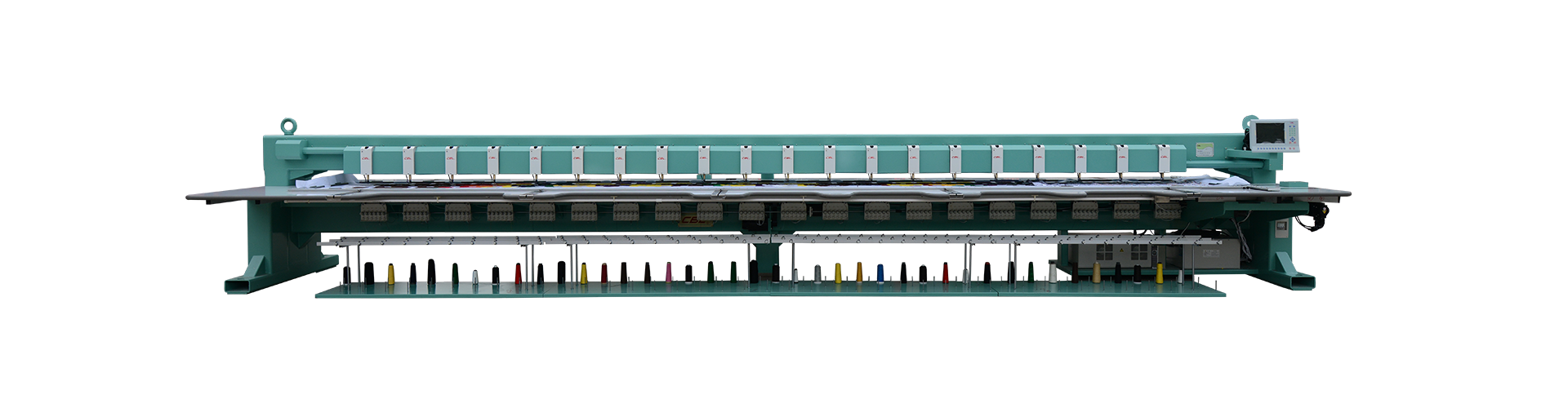

Chenille + Flatbed Type

Available in up to 24 heads, you can scale your chenille embroidery and traditional embroidery production with the 2-in-1 combined chenille embroidery machines.

Technical Parameters:

•Servo motor for main axis movement

•Servo motors for X and Y axis movements

•Intelligent thread break detection system

•Upper-thread holding system

• Automatic trimming

• AC motor for color change

• Motor-controlled jump stitch

• Integrated AC motor hooking system

• Servo motor for D shaft

• Servo motor for H shaft

• Stepping motor trimming for chenille embroidery

• Heavy duty linear guide rail for X and Y axis driving

• Reinforced frame materials

• Rail type of frame guide rail

• Heavy duty frame bearing

• No-contact inductive lever switch

• Thread break detection

• Automatic or manual color change, automatic start

• Cyclic embroidery, design editing and design combination

• Memory design display and preview

• Setting the offset point and save design origin point

• Forward and rewind designs at high and low speeds

• Rotate, resize, edit and multiply designs

• Edit design density and compensation directly on screen

• Design tracing helps ensure your needle does not hit the hoop

• Preset hoops set hoop boundaries for perfect centering

• Return to the start point or end point

• Multiple languages available

• Can chenille embroidery, monogram, mixed chenille and flat embroidery

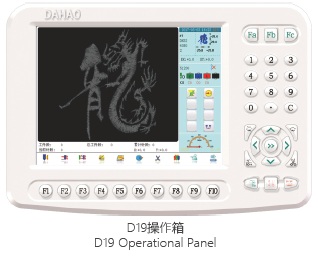

Control Panel Features:

- D19 is the upgraded version of C19 and its functions, operation mode and display interface are compatible with those of C19. D19 has extended many practical functions and upgraded configurations:

- New control system platform based on “Dahao Core” DH910 to comprehensively improve the control performance;

- New button operation mode with three more self-defined function buttons to have made operation more convenient;

- Color-changing times up to 1000 times;

- An increased memory capacity of 200 million stitches or 800 designs

- Support maximum stitch number for single pattern of 2 million stitches;

- Support intelligent encryption mode for payment installment

- Main board and control box to be connected by HDMI interface cable instead of flat cable for more convenient connection;

- Optimized looping embroidery control algorithm and high-speed looping drive technology to realize super high-speed rotation at 1200rpm;

- Support flat & looping embroidery double main shaft drive function;

- Support 2H/3H axis drive function;

- Support looping stepping closed loop color-changing function;

- Support flat & looping embroidery double color-changing function

- Support custom-made and special needle height potentiometer DW320 for looping embroidery;

- Support looping & flat embroidery combination function;

Division of Models

|

Model |

Flat | Chenille | Head interval |

Max speed for flat |

Max speed for chenille |

EMB area (mm) |

Machine dimension (mm) | ||||||||

| Needles | Heads | Needles | Heads | mm | SPM | SPM | X | Y | A | B | C | D | E | ||

| Length | max width |

height to table |

length | ||||||||||||

| MFC-60906H | 9 | 6 | 6 | 6 | 450 | 1000 | 850 | 450 | 750 | 4390 | 1955 | 1650 | 1380 | 1130 | |

| MFC-60912H | 9 | 12 | 6 | 12 | 450 | 1000 | 850 | 450 | 750 | 7090 | 1955 | 1650 | 1380 | 1130 | |

| MFC-60915H | 9 | 15 | 6 | 15 | 450 | 1000 | 850 | 450 | 800 | 8700 | 1955 | 1650 | 1380 | 1130 | |

| MFC-60918H | 9 | 18 | 6 | 18 | 450 | 1000 | 850 | 450 | 750 | 10500 | 1955 | 1650 | 1380 | 1130 | |

| MFC-60920H | 9 | 20 | 6 | 20 | 450 | 1000 | 850 | 450 | 800 | 11500 | 2035 | 1650 | 1380 | 1130 | |

Remarks:

- Head interval, embroidery area and needles can be specially made as per customers’ requests.

- MFC-H-stands for high speed mixed flatbed& chenille model

- OEM&ODM orders are welcome